A vibration meter, or vibrometer, is a device with which you can perform a comprehensive analysis of the condition of your machinery.

What is the difference between a vibrometer and a vibration meter?

These terms occur interchangeably, and it can be considered that in the world of maintenance, both terms refer to a not-so-complicated, portable instrument that uses a vibration sensor-accelerometer and display to indicate the level of vibration, most often intended to determine the condition of machinery. More sophisticated devices are called: vibration analyzers or data collectors.

Why measure vibrations?

A vibration meter for a machine operator, maintenance engineer or vibration diagnostician is like a thermometer for a doctor. The vibration level reflects the technical condition of the machine, and an elevated value gives the first indication of a possible malfunction, just as a fever is a symptom of a human disease.

What kind of vibration meter to buy?

If we want to quickly assess whether a machine is working properly, we need to get just a vibration meter. A proven vibrometer, necessarily coming from a specialist in vibration measurements, will be purchased for as little as several thousand zlotys. This will be an instrument in a suitcase set, with a minimum 3-year warranty, with access to spare parts and a calibration certificate. Be sure to look for an instrument with a sensor, cable and magnet. We can find some cheaper items on the market with a built-in sensor, but we must be aware that the quality of signal processing, especially in Far Eastern devices, leaves much to be desired and our readings may be difficult to interpret….

Adash Vibrio MS – Vibration meter (vibrometer) with vibration sensor, cable and magnet, in case set.

What does the vibrometer measure? How to interpret the results?

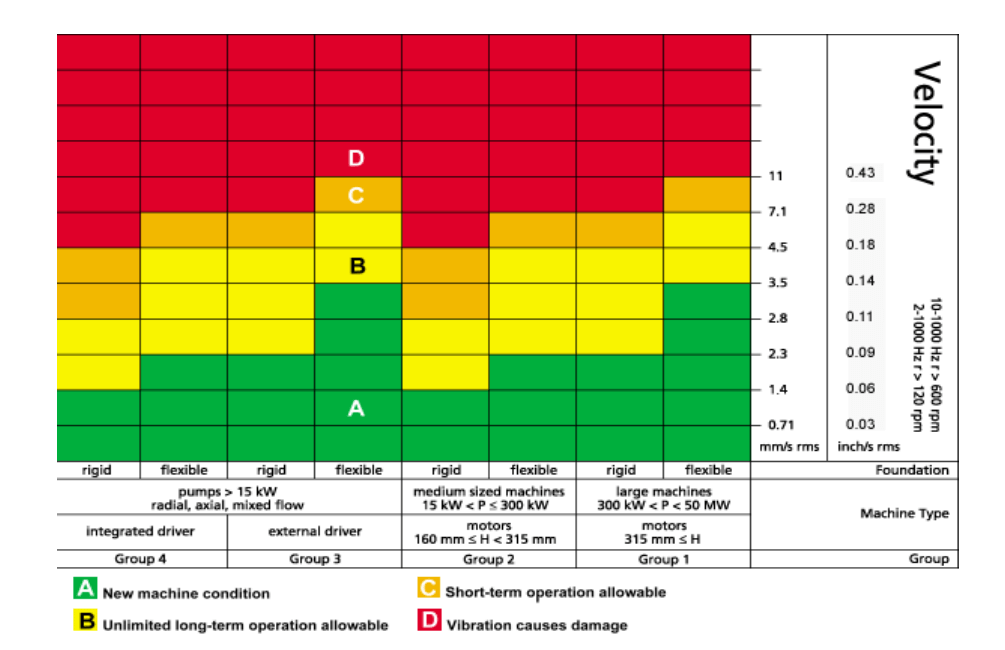

The basic parameter, indicated by the vibration meter, is the rms value of the vibration velocity, denoted as VRMS. Without going into mathematical details, it should be noted that the rms value of the vibration velocity VRMS reflects the energy level, represented by the vibration of the machine, so it is a good indicator, informing of the deteriorating condition of the machine, and it is a parameter referenced in ISO 10816 (ISO 20816).

The standard divides machines into different groups based on: speed, drive power, drive size, and how the machine is founded. For each group, colors specify thresholds:

- A for new machine condition,

- B of acceptable, long-term operation,

- C acceptable, short-term operation;

- D unacceptable.

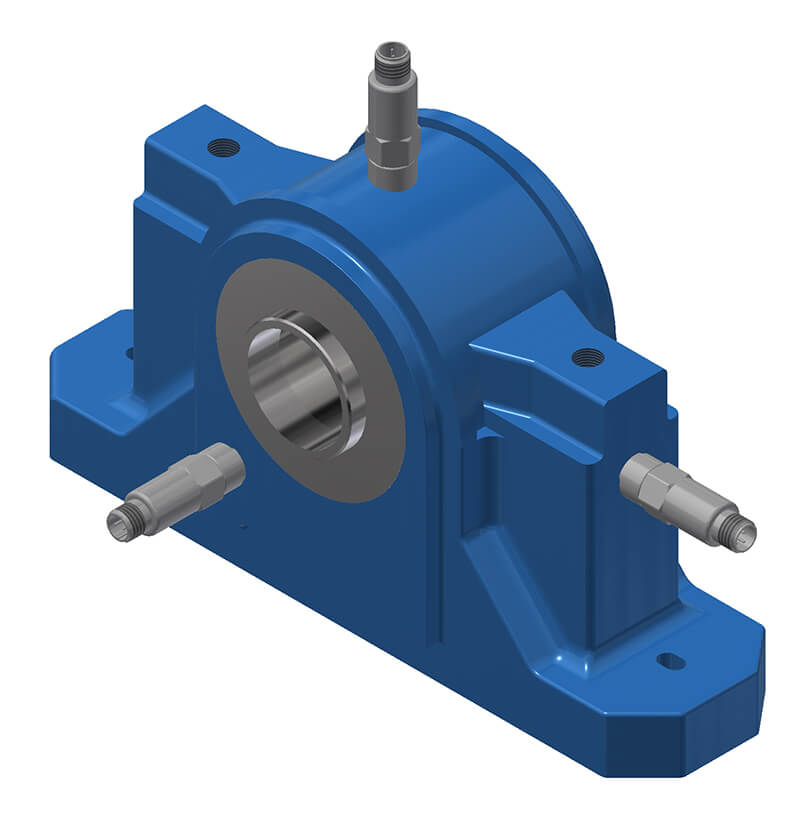

What parts of the machine to measure on?

We can measure vibrations on any parts of the machine, but the recommendations of the standard say to take measurements on the bearing housings, because on these parts, the emerging forces from rotating parts usually have the highest amplitude, hence the vibration level is usually the highest and thus our diagnosis is most effective.

How do we know if we have applied the vibration sensor correctly?

It is extremely important to measure vibration with the following principles:

- under the same operating conditions of the machine,

- at the same point,

- in the same way of application,

All these rules so that we are able to compare indications and assess any deterioration in the condition of the machine relative to previous measurements.

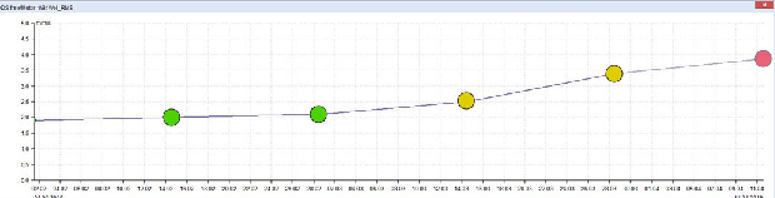

Vibration level trend with marked levels according to ISO 10816.

How to achieve repeatability of vibration measurements?

First, we make sure that the machine is operating under the same conditions, i.e. under the same load and at the same speed. We mark the measuring points so that the sensor application points, during subsequent measurements, are the same. This can be done with a marker, a permanent sticker or a special pad, glued at the mounting points. We apply the sensor on a magnet, which ensures the repeatability of the measurement, because we are independent of the angle of application and the pressure force of the sensor, as is the case with a measuring spike.